Water Management Strategies for Industry in Regional and Remote Communities – Part 1

November 25, 2019

21st Century Australia is preparing to face unprecedented challenges in the energy and water sector as it attempts to curb the impact of climate change.

Australia, more so than many Western economies, is highly exposed to the negative financial impacts of climate change. Extreme weather events such as drought have already had a huge influence on Australia’s food and mining sectors which were identified along with data on Australia’s drought trends in an article published by Hydroflux in February 2019, entitled “Can the Food Industry Survive Drought?”

This article can be found here.

Meanwhile, the potential for Australia’s food industry remains extremely positive – with a huge forecasted increase in demand from Asia for fresh, high quality produce fueling a strong growth in the sector. The resourceful nature of the Australian farming community in combination with our vast agricultural resources place Australia in prime position to be the “food bowl” for export growth. However, the impacts of climate change, drought and water shortage have the potential to curb this progress. Water is a critical resource for any industry, and many will consequentially look to practical solutions to recover and recycle water.

Many of Australia’s medium and large food processing facilities are located in regional and remote inland areas, significant distances from major cities. Drought and water scarcity in many of these areas have already devastated industry and communities alike. Currently almost a dozen significant inland cities are closing in on the controversially dubbed “Day Zero” (Peacock, 2019). Many will be familiar with this term, as it was coined for the Cape Town water crisis. The City of Cape Town, in a herculean effort was able to avoid total collapse by installing emergency seawater and groundwater desalination systems at considerable cost to the city.

Regional Australian centers and townships cannot rely on the same emergency solutions implemented in coastal regions like Cape Town. For inland cities such as Dubbo, Narromine and Cobar the only alternative water source is groundwater.

Groundwater sources provide their own challenges, as often the bores struggle to keep up with demand. For towns like Dubbo, the groundwater table is dropping, and bores are starting to fail (Davies, 2019). In many areas the groundwater is too saline to drink, so desalination is required. In some cases, public investment into huge fresh water pipelines (along with the huge energy consumption required for pumping) or even trucking water to struggling communities is being considered.

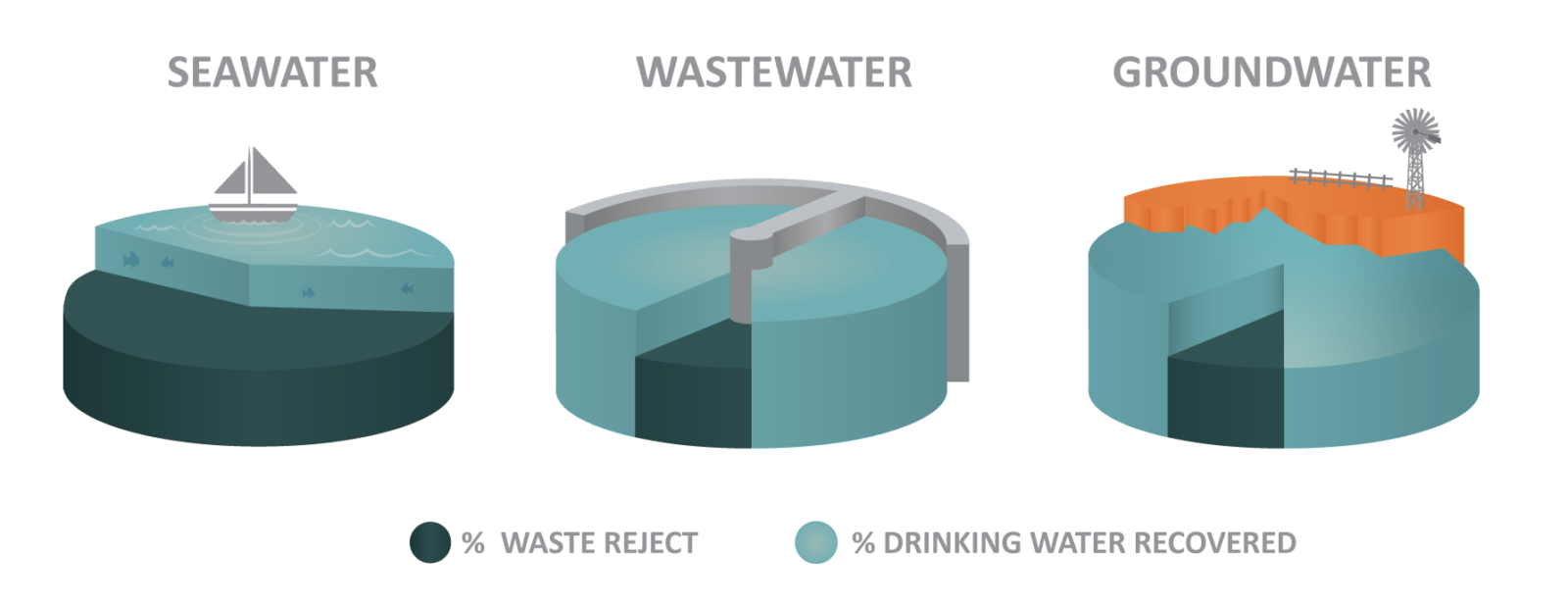

Regional industries must look at alternative solutions such as Advanced Water Treatment (AWT) to dramatically reduce fresh water consumption. AWT plants use the final stage of reverse osmosis to generate potable water from wastewater. This final process is very similar to that used for seawater desalination although considerably more economical in the percentage of potable water recovered from the feed water and energy usage as explained in the diagram below. Even when compared to desalinating “salty” groundwater, AWT applied to secondary treatment industrial wastewater usually offers the highest efficiency

When seawater is delivered to a desalination plant, approximately 65% of the feed is rejected as concentrated brine leaving 35% as a reusable product, whilst for industrial wastewater, the reject stream usually only amounts to 10% offering at least 90% recovery. The efficiency of desalinating ground water varies considerably and depends on the location, the concentration of salt in the aquifer and the presence of naturally occurring elements such as Iron. Ground water recovery rates generally vary from 50 – 90%.

Hydroflux Advanced Water Solutions for direct food contact involve reinjecting recycled water directly into the potable water supply as opposed to supplementing a mains water supply that may or may not be further treated. Hydroflux systems are fully compliant with the requirements of Food Safe Australia, Australian Quarantine Inspection Service (AQIS) and any relevant industry regulators.

For more information on Hydroflux HyPURE Reverse Osmosis system please click here.

Up Next

World Toilet Day 2019

Categories

- Tradeshows

- Climate

- Community Engagement

- Corporate Announcements

- Group News

- Newsletters

- Product News

- Project Announcement