Understanding Industrial Trade Waste: TDS – Part 4

October 30, 2020

Your trade waste agreement with the local water authority details acceptance standards with concentration limits of certain substances.

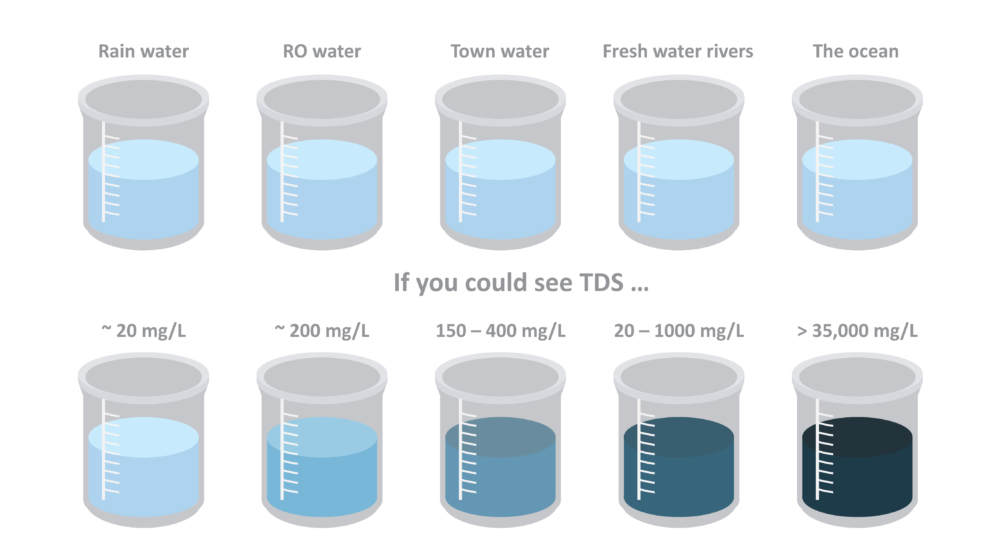

Some important substances were summarised in Understanding Industrial Trade Waste: Common Nomenclature – Part 3.TDS needs specific mention. TDS is known as either Total Dissolved Salts or Total Dissolved Solids and is used interchangeably.

TDS refers to any minerals, salts, metals, cations or anions dissolved in water. It comprises inorganic chemical salts (principally calcium, magnesium, potassium, sodium, bicarbonates, chlorides, and sulphates) and some small amounts of organic matter that are dissolved in water.

In the case of Sydney Water, acceptance standards for TDS are determined on a catchment specific basis. A limit of 500 mg/L may apply to customers discharging to an inland wastewater treatment plant (WWTP). This limit only applies to those discharging over 100 kg/day of TDS or greater than 1% of the total catchment TDS load (whichever is lower).

St Marys Advanced Water Treatment Plant is one of the largest recycling plants in Australia and is an inland WWTP operated by Sydney Water. It treats wastewater from Penrith, Quakers Hill and St Marys wastewater treatment plants to produce very high-quality recycled water.

This recycled water is released into the Hawkesbury-Nepean River at Penrith. This saves water stored in dams for drinking and keeps the river healthy.

However, if discharging to an ocean based WWTP, a limit of 10,000 mg/L applies. In any case, there is no charging rate associated with TDS to either inland or ocean based WWTP. But Sydney Water can impose fines for breaching the TDS limit relevant to your discharge.

Unfortunately, there is no cost-effective way to manage the TDS in trade wastewater – reverse osmosis can be used to remove TDS but will produce a much stronger reject stream called brine that will require off-site disposal – it cannot be discharged to sewer as it still exceeds the load limits imposed by trade wastewater agreements.

Reverse Osmosis (RO) such as Hydroflux HyPURE®, are a physical process used to remove trace organics as well as inorganic chemicals, and are used in situations where very high-quality water is required, for example in advanced treatment of wastewater allowing reuse. RO can remove > 99.5% of dissolved salts and up to 97% of most dissolved organics and is also effective in the removal of enteric pathogens.

Unless there is justification for both capital and operational expense of reverse osmosis based on the potential reuse, or there are other drivers for reuse that make this option attractive, the wastewater will need to be discharged to the environment.However, when discharging treated water to the environment, the TDS (particularly the inorganic chemicals and less so the organics) pose a hazard to the river ecosystems. Key hazards are:

- Boron, chloride, sodium, cadmium and chlorine are toxic to plants in large quantities (chlorine is also dangerous to aquatic organisms).

- Salinity causes water stress in plants, degrades soils and makes cadmium already in the soil more available to plants.

- Sodium excesses can cause soils to become sodic and can degrade soil structure, making it difficult for water and plant roots to penetrate the soil.

Ultimately managing TDS in wastewater becomes a balancing act involving minimising the amount of TDS introduced into the wastewater by Clean-In-Place (CIP) and the amount of waste product released, recycling and if necessary cleaning and CIP chemicals for reuse (for example there are caustic recovery processes available), or managing the brine stream produced.

Our R&D team has developed specific application technology to enable efficient brine disposal including accelerated evaporation ponds and crystallisation. Hydroflux Technology is the R&D company of the group.

Industrial Trade Waste Versus Equivalent Population – Part 1 – Click here.

Impact of Non-Compliance – Part 2 – Click here.

Understanding Industrial Trade Waste: Common Nomenclature – Part 3 – Click here.

Up Next

Hydroflux Group Newsletter – October 2020

Categories

- Tradeshows

- Climate

- Community Engagement

- Corporate Announcements

- Group News

- Newsletters

- Product News

- Project Announcement