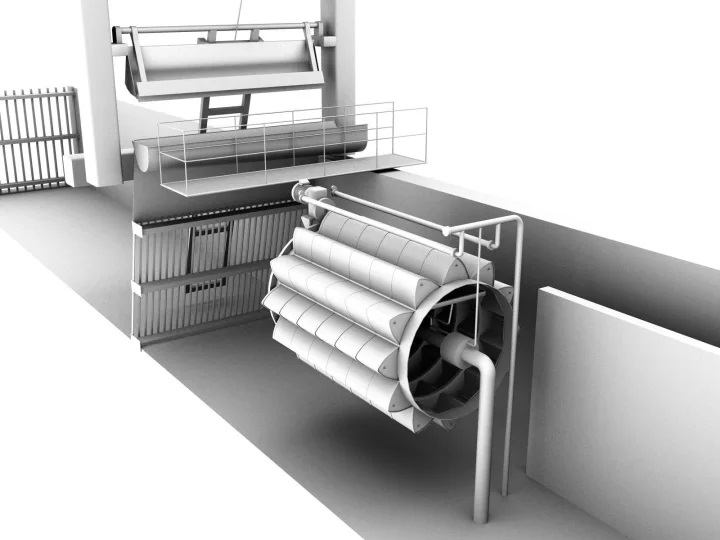

Rotary Drum Filters

Flootech Oy offer a wide range of Rotary Drum Filter solutions to treat various water sources for use in cooling towers, municipal desalination plants and for industrial process water make-up.

The screening solutions can be used for fresh and seawater intakes. With installations dating back to the 1960’s, Flootech’s Rotary Drum Filter’s are industry proven, robust and offer clients with significantly lower total cost of ownership compared with traditional drum filters.

Flootech Rotary Drum Filters can be combined with Dual Flow Basket Filters to provide complete intake solutions with very high filtraiton grades (35 – 50 micron).

Find out more

Flootech Oy offer a wide range of Rotary Drum Filter solutions to treat various water sources for use in large scale cooling towers, municipal desalination plants and for industrial process water make-up.

The screening solutions can be used for fresh and seawater intakes. With installations dating back to the 1960’s, Flootech’s dual flow basket screens are industry proven, robust and offer clients with significantly lower total cost of ownership compared with traditional drum filters.

The Flootech’s Rotary Drum Basket Filter has a wide range of applications, including the following:

• Aquaculture Continuous Flow Through and Batch Grow Out Facilities

• Mining Process Facilities

• Oil & Gas Refineries

• Power Stations

• Petrochemical Industries

• Steel Mills

• Ship & Barge intake systems

• Municipal Desalination Plants

Flootech Rotary Drum Filters can be combined with Dual Flow Basket Filters to provide complete intake solutions with very high filtration grades (35 – 50micron).

Flootech Oy offer a wide range of Rotary Drum Filter solutions to treat various water sources for use in large scale cooling towers, municipal desalination plants and for industrial process water make-up.

The screening solutions can be used for fresh and seawater intakes. With installations dating back to the 1960’s, Flootech’s dual flow basket screens are industry proven, robust and offer clients with significantly lower total cost of ownership compared with traditional drum filters.

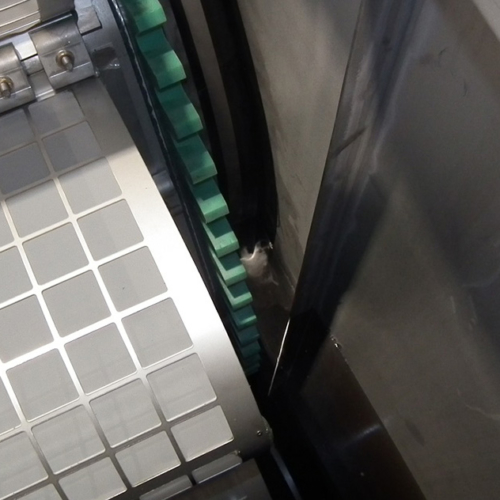

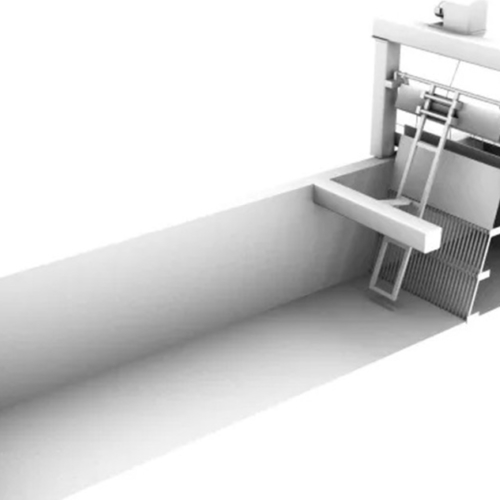

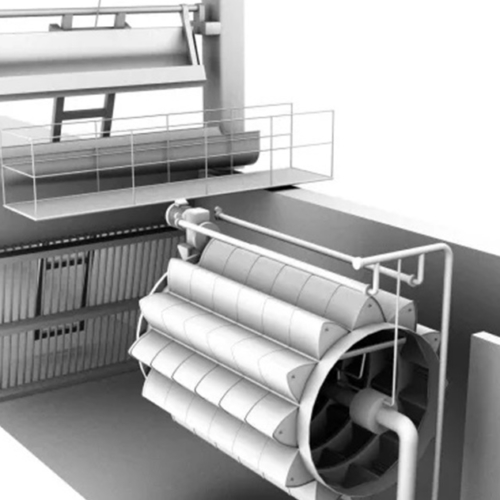

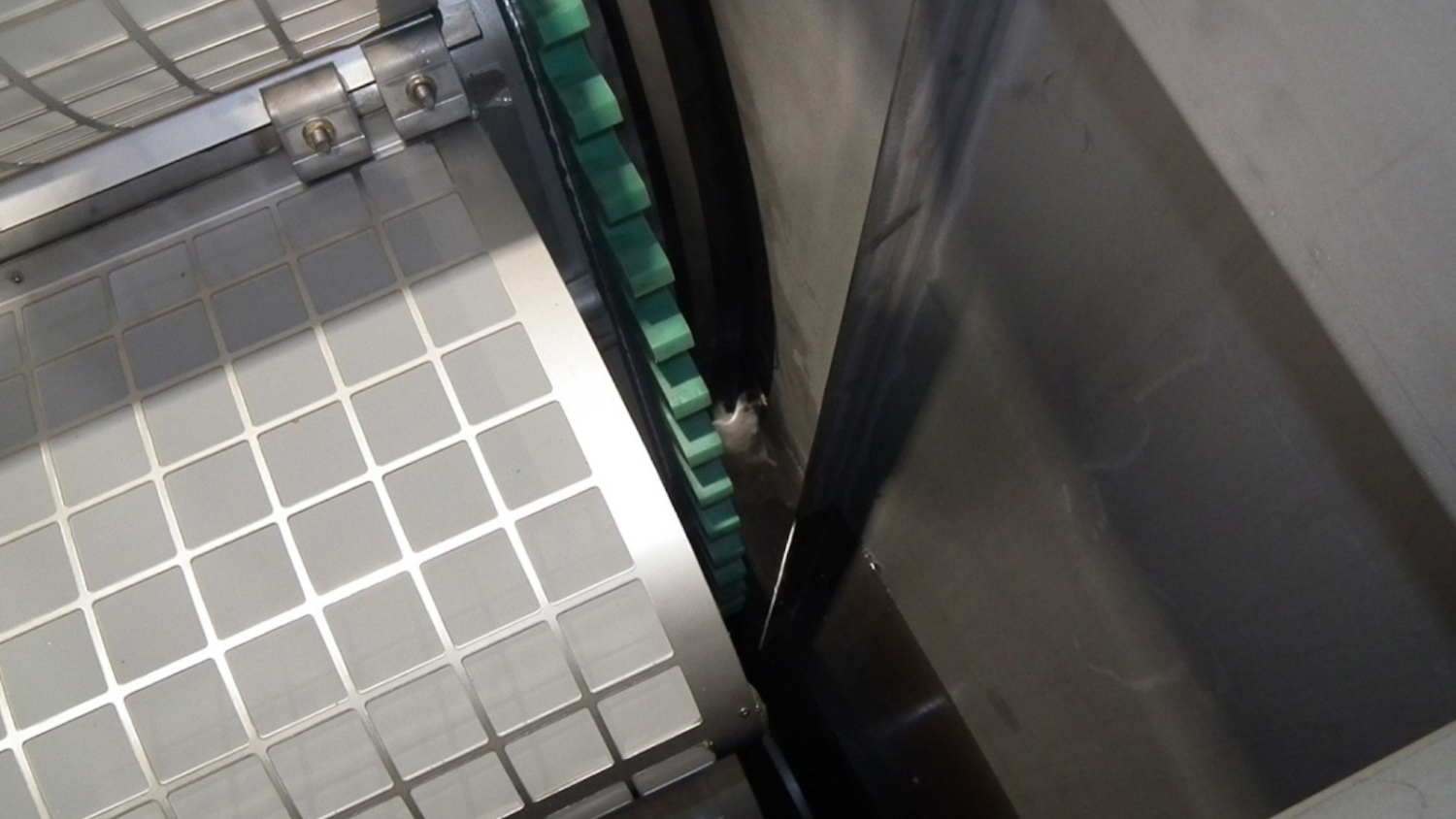

The Flootech Rotary Drum Basket Filters are designed to provide preliminary filtration and gross solids removal from water down to 35micron.

Water enters the holding tank and into the center of the drum. Fine screenings are filtered from the water as it passes from the inside of the filter to the outside. From here the water flows over a weir within the holding tank to the discharge pipe.

Cleaning of the screen is performed automatically via a wash water system. The washing cycle is controlled by a timer, which is typically 10% of the operating time. External wash jets clean the filter and push debris into the central collector, where it is removed for disposal via the discharge pipe. The clean surface of the screen then travels back down into the feed channel. The wash cycle continues until the downstream water level returns to normal.

The Flootech Rotary Drum Filters have several advantages over traditional drum screens. One significant advantage is the very high surface area for the required installed tank volume (m2/m3), which is only possible due to the unique design of the drum. This provides the Flootech Rotary Drum Basket Filters with significant capital and operating costs savings compared with current technologies.

Flootech Rotary Drum Filters can be combined with Dual Flow Basket Filters to provide complete intake solutions with very high filtration grades (35 – 50micron).

Hydroflux Industrial exclusively provides complete design, build, install and refurbishment service for Flootech Raw Water Screens throughout Australia, New Zealand and the Pacific Islands. Our commitment to our clients does not end with the delivery of the project and we support our clients so that that their plants continue to operate at their full design capacity well into the future.