High-Rate Anaerobic Systems UASB & ECSB

Hydroflux is proud to be Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for our entire organization. As part of our climate change mission, we continue to research, develop and invest in sustainable technologies.

Now our journey continues – our main range of water technology and associated chemical products are Climate Active certified as carbon neutral. To read more on our journey, click HERE

UASB and ECSB high-rate anaerobic treatment plants are ideal for industrial wastewaters with high COD concentrations.

Digester types UASB & ECSB

UASB & ECSB reactor systems will typically convert up to 80% of the COD in the wastewater into valuable biogas.

They are relatively simple to install and contain no internal moving parts or rotating equipment inside the reactor, requiring minimal maintenance.

UASB

The Upflow Anaerobic Sludge Blanket Reactor – UASB is the most commonly applied anaerobic technology for the biological treatment of high strength industrial wastewater. Typical organic loading rates for UASBs are 5-15 kg/COD/m3.d

ECSB

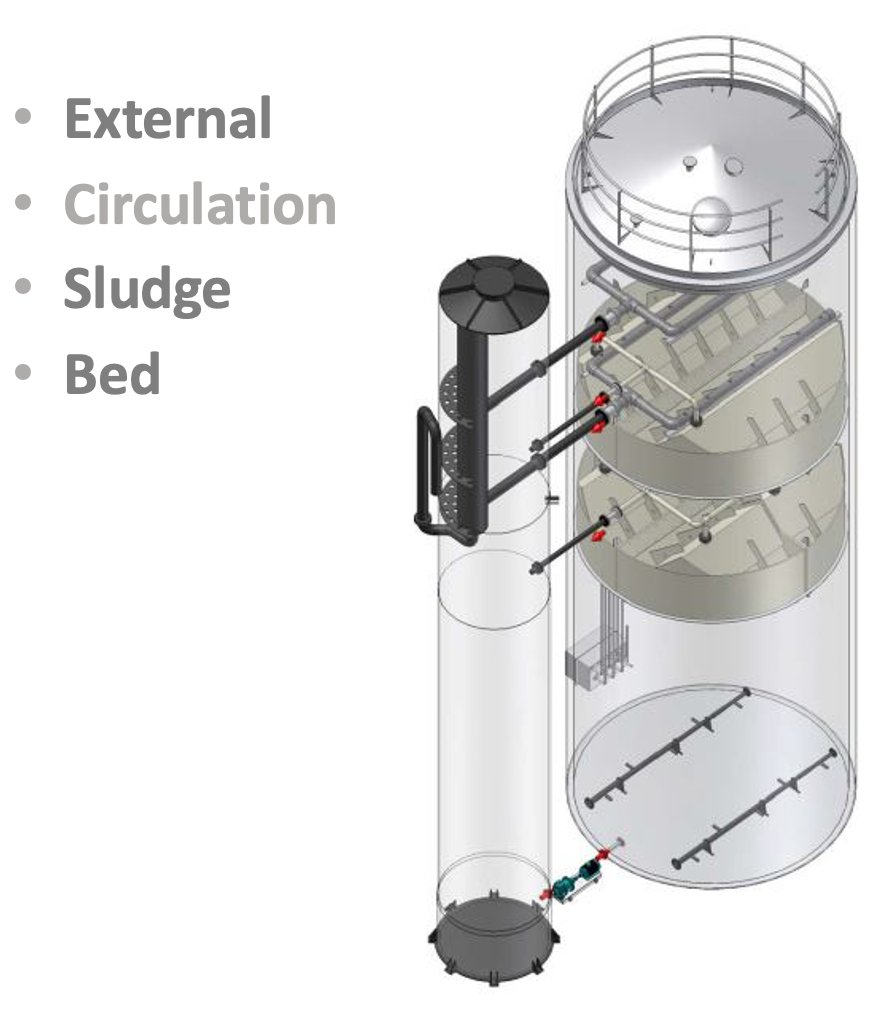

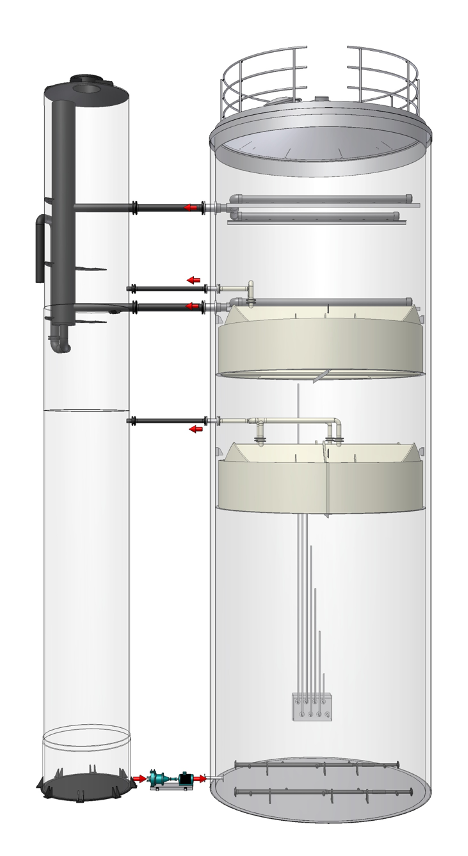

The External Circulation Sludge Bed Reactor – ECSB is a two-stage anaerobic high-rate process with proven success in many industries for wastewater with very high COD loads. Typical organic loading rates for ECSBs are 15-35 kg/COD/m3.d

Find out more

The UASB (Upflow Anaerobic Sludge Blanket) process is the most applied anaerobic technology for the biological treatment of high-rate industrial effluents.

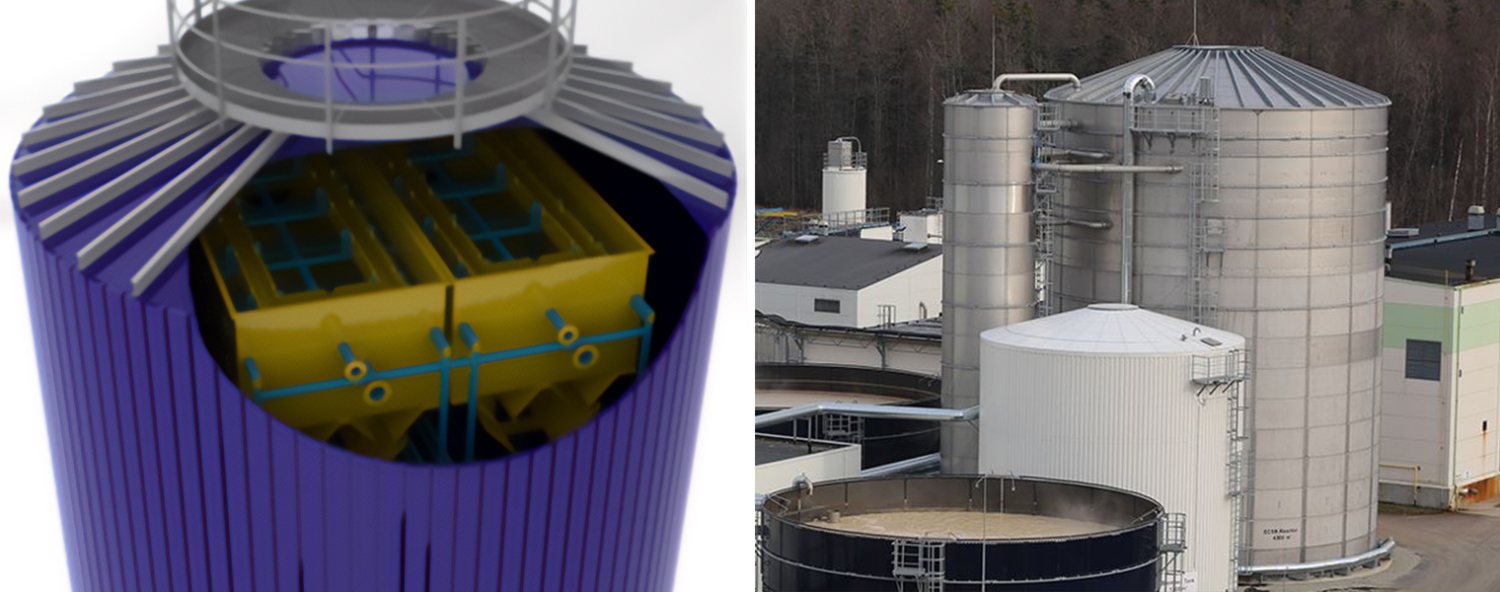

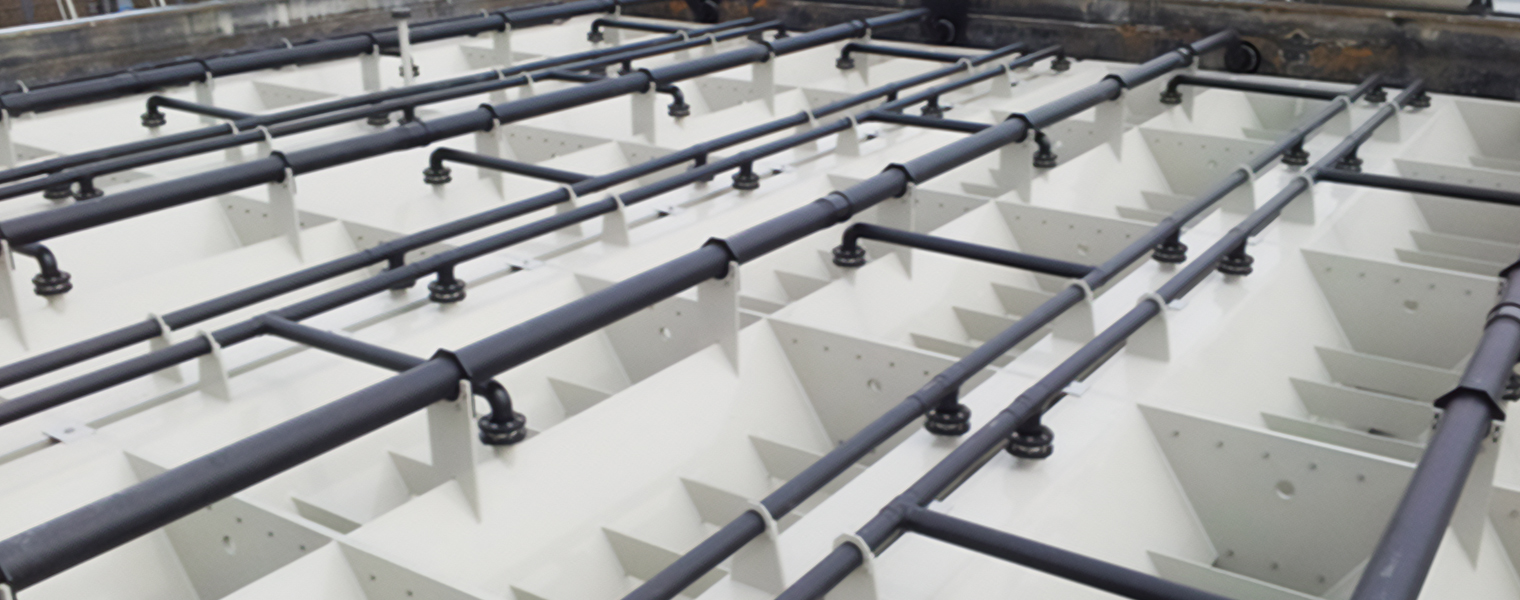

UASB use gas/liquid/solids (GLS) separators and overflow weirs in the digester top section to separate biogas and biomass and settle and return biomass to the digester sludge bed.

Gas / Liquid / Solids separator inside UASB Reactor

Typical characteristics of UASB Reactors are:

- Maximum process stability due to controlled external re-circulation flow which is not depending on the influent COD/flow

- Due to the ability to store gas, a separate biogas holder may not be required

- Phase separators constructed of PP, eliminating risk of corrosion

- No complex or rotating equipment inside the reactor requiring maintenance

- Loading rates are typically in the range of 5 – 15 kg COD/m3 .day

The Hydrothane ECSB is a proven high-rate anaerobic system that uses anaerobic bacteria (biomass) to convert organic pollutants or COD (chemical oxygen demand) into biogas in an oxygen-free environment. The system comprises two vessels being the neutralisation tank and the main reactor. The main reactor contains a highly efficient phase separator that retains the sludge as the water passes though to the point of discharge.

Features

- The Hydrothane system is suitable for many types of industrial wastewater with high COD loads

- It is a compact design utilising reactor vessels up to 20 m tall. The reactor materials of construction are flexible depending on the size, availability and cost. They can be constructed from Steel (stainless or coated carbon, welded or bolted), concrete or FRP (fiberglass-reinforced plastic)

- The system is fully sealed so there are no odour emission points

- There are no complex internal mechanisms that require maintenance

Industrial wastewater may require pre-treatment in the form of screening followed by clarification or dissolved air flotation prior to anaerobic treatment for the removal of gross solids and to reduce the concentrations of oil and grease. Some additional wastewater conditioning may also be necessary to ensure that there are sufficient nutrients and trace metals, and the temperature and pH are within a suitable range.

General process description

- Pre-treated and conditioned wastewater enters the neutralisation tank.

- The recirculation pump transfers wastewater into the sludge bed in the base of the ECSB reactor at a rate several times greater than the feed flow

- The wastewater flow up the ECSB reactor through phase separators to retain solids (anaerobic biomass) within the system.

- The clarified wastewater flows over weirs near the top of the reactor to the point of discharge

- Biogas is collected at the top of the neuralisation tank and ECSB for further processing and reuse.

Biogas is a mixture of gases produced during the anaerobic digestion of organic matter. It is generally composed of 60–65% methane (CH4) and 35–40% carbon dioxide (CO2). Minor constituents are hydrogen sulphide (H2S), nitrogen (N2), hydrogen (H2).

There are many uses for biogas although in industrial applications biogas is most commonly used as an alternate fuel source for boilers and when in sufficient quantities converted to electricity. When biogas is used as a fuel it must be carefully conditioned to the specification required for its intended use.

A gas flare is always installed to allow biogas to be safely burned off whether biogas is being reused or not and treatment of biogas to remove impurities is essential.

Biogas treatment equipment.

Hydroflux supply a range of biogas treatment systems that are engineered to maximise the recovery and utilisation and will comprise:

Biogas collection

Positive displacement blowers will often be required to transfer biogas from the covered anaerobic lagoon at a controlled rate and pressure to downstream equipment

Biogas Chilling

Digester produced biogas is 100% water saturated as as it cools in the lines to the point of reuse, large amounts of water will condense in the piping system . Hydroflux will incorporate the most suitable biogas cooling system into the treatment process

Biogas Treatment

Removal of hydrogen sulphide from biogas is essential to avoid rapid corrosion. Hydroflux offer a range of chemical, media or biological gas scrubbers that will ensure that the biogas is suitably conditioned for reuse.

The Hydrothane ESCB is suitable for the treatment of wastewater from many industries and is ideal for high COD loads in excess of 5 T per day when biogas recovery is most beneficial. Anaerobic treatment will not remove nutrients and a second aerobic stage is necessary for environmental discharge.

- Meat and poultry industry

- Dairies

- Beverage sector

- Fruit and vegetable processing

- Potato and potato chips

- Vegetable oil processing

- General Food industry

- Manufacturing

- Industrial laundries

- Paper, cardboard and printing

Is anaerobic treatment suitable for my application?

There are a number of factors to consider which will determine whether anaerobic digestion of your wastewater is a suitable solution. Firstly an anaerobic treatment plant will not remove BOD to levels that allow discharge to the environment or for reuse, nor will it reduce the levels of nutrients. In saying this however, for high COD loads, anaerobic digestion upstream of an aerobic process such as the Hydroflux SBR, MBR, MBBR will significantly reduce the load on the aerobic process lowering the overall capital and operating costs of the treatment plant whilst having the possibility of generating and reusing biogas.

Anaerobic treatment is best suited to relatively high flows and for economical gas recovery generally over 3-4T of COD a day would be necessary.

How much space will I need?

Each system is designed to suit the specific characteristics of the wastewater in question however, the Hydrothane ESCP process is however one of the most compact anaerobic systems available worldwide utilising tall reactors that save on surface area. The reactors can extend up to 20m high.

The main reactor itself is usually sized based on a loading rate of 15-35 Kg COD / m3 / day, thus for a COD load of 3000Kg per day, the diameter of the main reactor could be as little as 5m.

How much biogas will the system generate?

The amount of gas generated depends on a number of factors but of most value is the COD load. As a rule of thumb for every Kg of COD, 0.35m3 of biogas will be generated. This biogas will need to be conditioned for reuse as it will be contaminated with carbon-dioxide (CO2) along with some trace gasses such as hydrogen sulphide (H2S), nitrogen (N2), hydrogen (H2) and oxygen (O2).

Hydroflux employs qualified civil, mechanical, chemical and electrical engineers plus a team of experienced project managers, site supervisors, commissioning engineers and service technicians based in offices in most capital cities providing a local presence throughout the duration of the project.

All projects are conducted under externally approved occupational health and safety, and environmental management systems.

Hydroflux is Australia’s first Water-tech company to achieve Climate Active certifications which means his means you are engaging with a carbon neutral organisation without increasing your carbon footprint and you are supporting positive and verified action on climate change.

A Hydrothane ECSB reactor being delivered to site.

Hydroflux can complete all the following works in house which are typically required to construct a wastewater treatment plant.

- Process design, development of PID’s and HAZOPS reviews

- Establishment of the most suitable wastewater treatment plant layout

- Equipment and component selection

- Civil and building designs including preparation of documentation for council or other regulators

- Electrical design and programming

- Project management and site supervision

- Environmental / Occupational health and safety plans and report

- Quality assurance plans

- Earthworks, civil works, building works, mechanical and electrical installation

- Commissioning, training and documentation as required.

Covered anaerobic lagoon at a rendering facility prior to commissioning