Flootech MBBR

The MBBR process is a highly flexible aerobic process ideally suited to the variability found in industrial wastewaters.

Some of the main features of the FlooBed® MBBR technology include:

- The high concentration of biomass attached to the media within the aeration zone effects smaller tankage and a lower footprint.

- The MBBR can be designed for partial or full removal of organics – The partial removal of organics is particularly beneficial in trade waste or sewer discharge applications where discharge limits for cannot be achieved by primary treatment alone.

- Nutrient removal is readily achieved by the introduction of pre-anoxic zones and mixed liquor return (MLR).

- Conventional activated sludge plants can often be upgraded to an MBBR process allowing the treatment of considerably larger flows or organic loads without increasing the wastewater treatment plant footprint.

Find out more

A FlooBed® MBBR is one of several types of aerobic biological wastewater treatment process that uses bacteria to consume organic matter in the presence of oxygen. The main difference between the FlooBed® MBBR and other conventional processes is that is uses small plastic carrier elements in the biological aeration vessel to provide a high surface area for biomass to attach to and grow. These carrier elements allow a very high concentration of biomass to be present in the bioreactor which effectively increases its biological treatment capacity and allows greater volumes of wastewater to be treated in considerably smaller vessels.

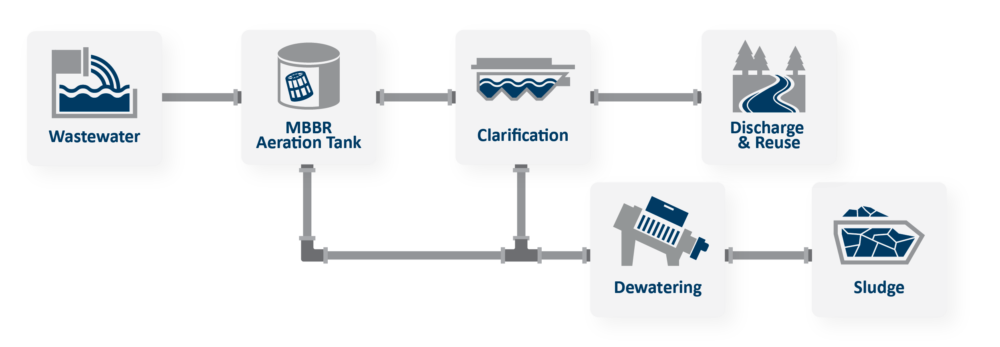

The stages of the MBBR process

- Wastewater is introduced into the aeration tank containing the carrier elements at a constant flow rate where oxygen is introduced.

- Biologically treated wastewater flows out of the aeration tank directly into a HyDAF system.

- The HyDAF system removes the biomass in the wastewater via flotation and the treated water flows to the point of discharge.

- The removed biomass is either dewatered and further processed or removed from site as waste activated sludge (WAS). Some biomass is returned back to the aeration tank as return activated sludge (RAS).

MBBR reactor at a food processing plant.

Nutrient removal

Nitrogen removal can be incorporated into the MBBR process by the inclusion of an anoxic zone upstream of the aeration tank with a mixed liquor return loop that recirculates water between the aeration and anoxic tanks.

Some phosphorous will be taken up in the biological process however if very low concentrations are required, the simple addition of coagulant to the DAF inlet will precipitate phosphorous from the clarified water stream.

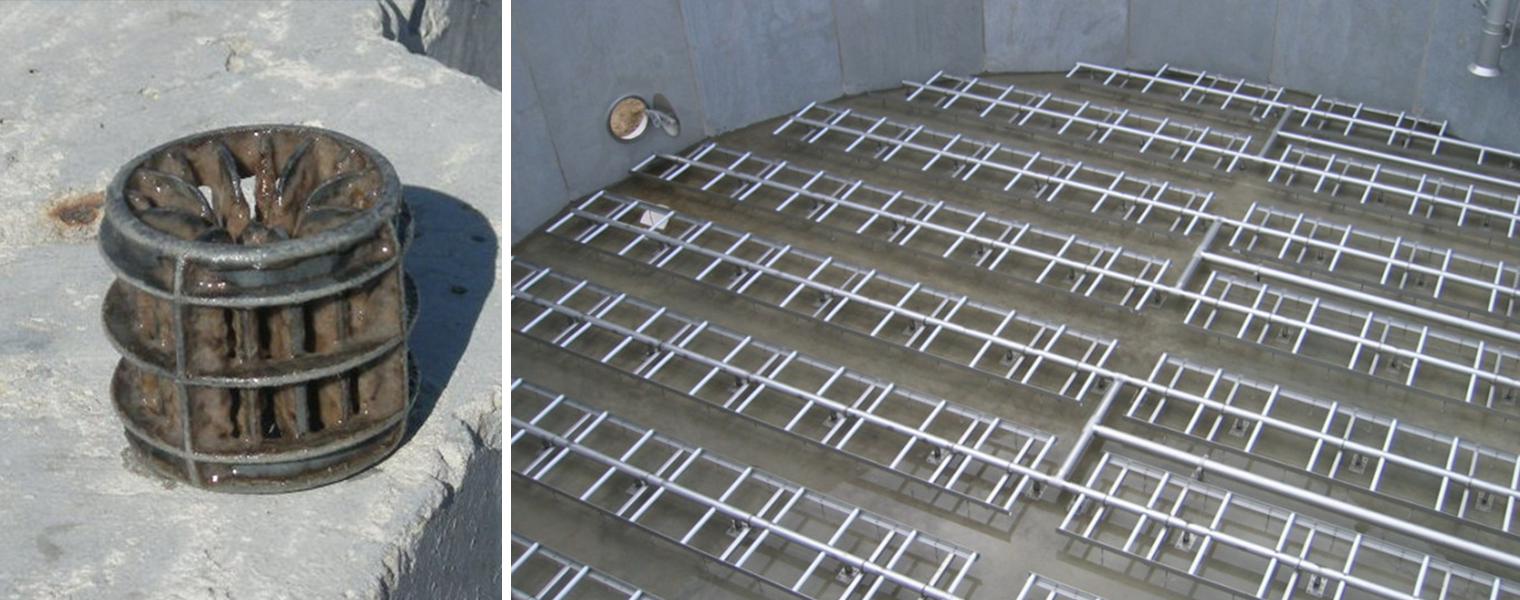

The design of the carrier is critical to the performance of the MBBR process and not all carriers are the same.

The carriers used in the FlooBed® MBBR are designed based on many years of experience with an engineered shape, opening, and surface area. It is this openness and shape that has been instrumental in maximising biofilm mass transfer and preventing clogging which otherwise leads to excessive maintenance. All of our carriers are sustainably manufactured primarily from recycled PE and injection molded to provide a hard and durable biofilm carrier that are resistant to cracking and distortion.

Left: Typical MBBR carrier coated in biomass Right: MBBR aeration grid offers high efficiency oxygen transfer whilst maintaining the carriers in suspension.

High quality and efficient aeration grids that utilises the entire tank surface area

Process oxygenation and mixing is performed by an advanced aeration system installed in the bottom of the FlooBed® MBBR aeration basin. The aeration system covers the entire bottom area allowing the most efficient use of the capacity and surface area.

Our aeration system is non-clogging and a practically service free system. The high degree of prefabrication ensures excellent quality and reduces the onsite installation time.

The function of the HyDAF system is to separate the biomass from the treated wastewater downstream of the MBBR reactor. The floated biomass is removed from the surface of the DAF by a mechanical scraper and drops into an integrated storage hopper. From here, the biomass is either returned to the bioreactor as return activated sludge (RAS) or dewatered and removed from site as waste activated sludge (WAS).

Waste activated sludge (WAS) is typically dewatered in a Huber screw press to a spadeable cake which can be further processed or composted.

Left: Primary HyDAF and post MBBR secondary HyDAF and screw press at a food and beverage facility in Sydney. Right: A screw press dewatering MBBR sludge achieving dry solids concentrations of over 15%.

MBBR’s are ideally suited for the treatment of industrial wastewater specifically to remove organics and nutrients.

- Meat and poultry industry

- Dairies

- Beverage sector

- Fruit and vegetable processing

- Potato and potato chips

- Vegetable oil processing

- General Food industry

- Manufacturing

- Industrial laundries

- Paper, cardboard and printing

A wastewater treatment plant utilising the MBBR process at a food processing plant.

Capacities

There is no limit on the capacity of the system as the size of the main MBBR vessel is dependent on the influent characteristics and output requirements and operated to suit. Hydroflux has constructed MBR systems to treat from 20 KL/day to 10 ML/day.

For larger systems, the MBBR is usually configured in multiple tanks to reduce construction costs.

A wastewater treatment plant utilising the MBBR process at a paper mill.

Conversion of existing aerobic systems to MBBR can improve the performance of your wastewater treatment plant.

If your plant is undersized for your current operations in terms of hydraulic or organic load, converting the aerobic process to an MBBR can produce excellent results. The key to such an augmentation is the increase in biomass population in the aerobic reactor as a direct result of installation of the carriers. Some modifications may be required to the aeration or clarification system however MBBR conversion is often a suitable and cost-effective approach to increase the capacity of your system by up to 50% without increasing the footprint.

Hydroflux employs qualified civil, mechanical, chemical and electrical engineers plus a team of experienced project managers, site supervisors, commissioning engineers and service technicians based in offices in most capital cities providing a local presence throughout the duration of the project.

All projects are conducted under externally approved occupational health and safety, and environmental management systems.

Hydroflux is Australia’s first Water-tech company to achieve Climate Active certifications which means his means you are engaging with a carbon neutral organisation without increasing your carbon footprint and you are supporting positive and verified action on climate change.

Construction of a complete wastewater treatment plant incorporating MBBR at a food processing plant in Queensland.

Hydroflux can complete all the following works in house which are typically required to construct a wastewater treatment plant.

- Process design, development of PID’s and HAZOPS reviews

- Establishment of the most suitable wastewater treatment plant layout

- Equipment and component selection

- Civil and building designs including preparation of documentation for council or other regulators

- Electrical design and programming

- Project management and site supervision

- Environmental / Occupational health and safety plans and report

- Quality assurance plans

- Earthworks, civil works, building works, mechanical and electrical installation

- Commissioning, training and documentation as required.

The MBBR process used the highly efficient HyDAF system for MBBR clarification.