Activated Sludge

Activated sludge is a conventional aerobic process that has its place industrial wastewater treatment.

Some of the main features of the Hydroflux Activated sludge process include:

- Aeration can be conducted in above ground tanks or ponds using a variety of aeration methods.

- Settlement of biomass occurs in a conventional clarifier or DAF system.

- Activated sludge plants can be easily configured for high efficiency Biological Nutrient Removal (BNR) by incorporation of anoxic zones.

- Chemical phosphorous removal can be incorporated into the clarification process.

Find out more

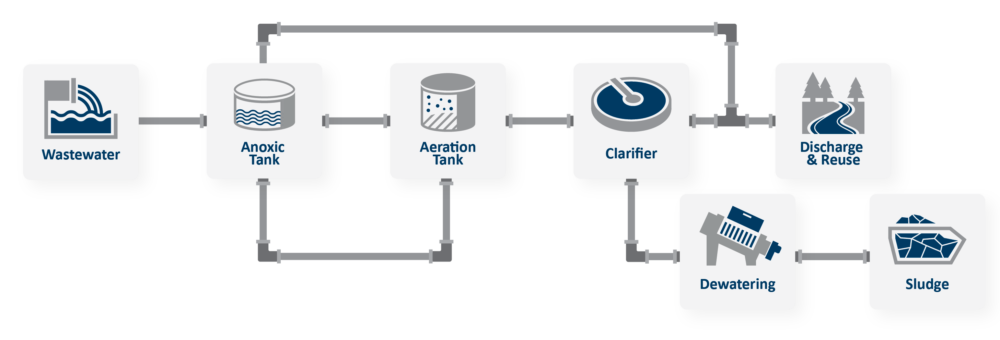

The activated sludge process is a conventional aerobic treatment system incorporating an anoxic zone and an aeration zone followed by clarification of biomass. Biomass clarification can be conducted in a clarifier or HyDAF system. In industrial applications DAF systems are becoming increasingly popular due to the small footprint and improved performance.

The stages of the activated sludge process

Wastewater is introduced into the aeration tank at a constant flow rate where oxygen is introduced

Biologically treated wastewater flows out of the aeration tank directly into a clarifier or HyDAF system

The clarifier or HyDAF system removes the biomass in the wastewater and the treated water flows to the point of discharge

The removed biomass is dewatered and further processed, or removed from site as waste activated sludge (WAS). Some biomass is returned back to the aeration tank as mixed liquor return (MLR) when nutrient removal is required.

Nutrient removal

Nitrogen removal can be incorporated into the activated sludge process by the inclusion of an anoxic zone upstream of the aeration tank with a mixed liquor return (MLR) loop that recirculates water between the aeration and anoxic tanks.

Some phosphorous will be taken up in the biological process however if very low concentrations are required, a simple addition of coagulant at the clarification plant inlet will precipitate phosphorous from the clarified water stream.

Activated sludge plants be configured in above ground tanks or ponds using various types of aeration methods including fine bubble diffusers, surface aerators and submersible aerators.

Our preference is to utilise Aerostrip fine bubble diffusers where possible as they offer the most sustainable solution in terms of power demand The most suitable means of aeration depends on the configuration of the aeration basin and the oxygen requirements.

Left: Surface aerators are most suited to pond systems. Right: Installation of Aerostrip diffusers in an aeration tank.

The function of the clarifier is to separate the biomass from the treated wastewater stream using settlement or floatation.

The clarifier relies on settlement of the biomass into the base from where it is withdrawn and dewatered. Hydroflux designs and constructs a range of different clarifies to suit each application.

Clarification

The clarifier relies on settlement of the biomass into the base from where it is withdrawn and dewatered. Hydroflux designs and constructs a range of different clarifies to suit each application.

A clarifier at a meat processing plant after as part of an activated sludge process.

Dissolved air flotation

Dissolved air flotation is a good alternative to clarifiers in industrial wastewater applications and offers a number of advantages.

- Dissolved air flotation systems operate with surface loading rate of at least 5 time greater than clarifiers significantly reducing the footprint required.

- The sludge generated by the DAF system contains a considerably higher percentage of dry solids resulting is lower waste activated sludge volumes to be further processed

- As the dissolved air flotation system removes biomass via flotation, scum and buoyant biomass that can form due to upsets in the biological process are still removed.

Whether the biomass is removed by settling or flotation, it is either returned to the bioreactor as return activated sludge (RAS) or dewatered and removed from site as waste activated sludge (WAS.)

Waste activated sludge (WAS) is typically dewatered in a screw press to a spadeable cake which can be further processed or composted.

Huber screw presses can achieve waste activated sludge dry solids concentrations of over 15%.

Activated sludge systems are well suited for the treatment of industrial wastewater and to remove organics and nutrients.

- Meat and poultry industry

- Dairies

- Beverage sector

- Fruit and vegetable processing

- Potato and potato chips

- Vegetable oil processing

- General Food industry

- Manufacturing

- Industrial laundries

- Paper, cardboard and printing

There is no limit on the capacity of the activated sludge plants with designs exceeding 10 ML/day.

Hydroflux employs qualified civil, mechanical, chemical and electrical engineers plus a team of experienced project managers, site supervisors, commissioning engineers and service technicians based in offices in most capital cities providing a local presence throughout the duration of the project.

All projects are conducted under externally approved occupational health and safety, and environmental management systems.

Hydroflux is Australia’s first Water-tech company to achieve Climate Active certifications which means his means you are engaging with a carbon neutral organisation without increasing your carbon footprint and you are supporting positive and verified action on climate change.

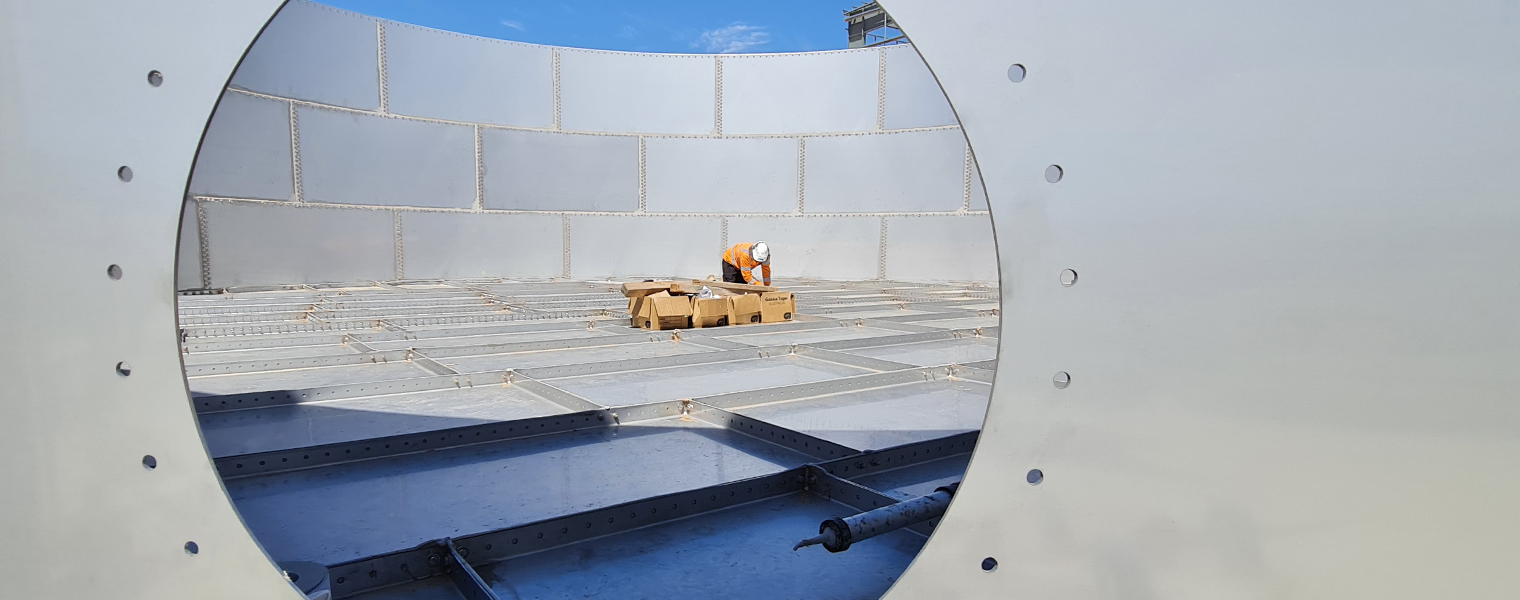

Construction of a turnkey wastewater treatment plant at a new food production facility in SA.

Hydroflux can complete all the following works in house which are typically required to construct a wastewater treatment plant.

- Process design, development of PID’s and HAZOPS reviews

- Establishment of the most suitable wastewater treatment plant layout

- Equipment and component selection

- Civil and building designs including preparation of documentation for council or other regulators

- Electrical design and programming

- Project management and site supervision

- Environmental / Occupational health and safety plans and report

- Quality assurance plans

- Earthworks, civil works, building works, mechanical and electrical installation

- Commissioning, training and documentation as required.

Stainless steel panel tanks are often used for aeration tanks.