Power

Hydroflux have a range of bespoke water solutions for the power industry. A snapshot of our capabilities are highlighted below.

- Raw cooling water intake screening

- Demineralised water treatment systems

- Condensate Polishing

The Hydroflux Industrial team consists of water and wastewater experts who are experienced in the delivery of projects for the power sector. Our teams includes the specialist engineers, project managers, chemists draftspersons and service technicians necessary to design and construct customised water treatment systems.

Find out more

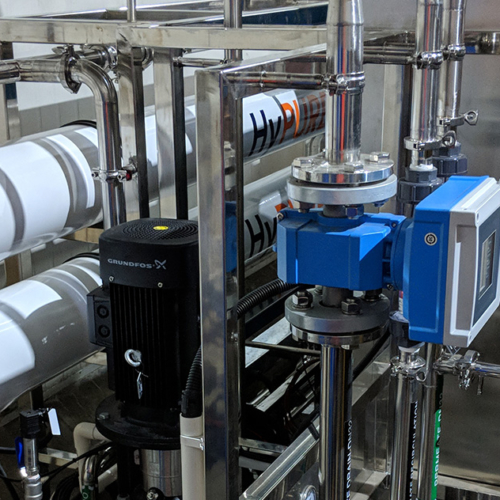

The reliable supply of demineralized water is critical for the operation of power stations.

Due to the sensitive nature of the boiler systems and turbines to fouling/scaling, the demineralisation systems are required to reach purity levels in excess of 17 MOhms/cm. Hydroflux are specialists in the design and construction of demineralized water solutions from 1 – 1,000 m3/hr. Our team understand the strict safety, quality and validation expectations from the Power industry. Through a collaborative design process, we customize our solutions to meet each client’s individual needs.

Hydroflux Solutions

Hydroflux offer a complete range of demineralized water and condensate polishing solutions for power stations including:

- Dissolved Air Flotation for highly turbid surface water supplies

- Multimedia Filtration

- Ultrafiltration

- Cation/Anion Ion Exchange

- Single and Double Pass Reverse Osmosis

- Electrodeionization

- Mixed Bed Ion Exchange

- Membrane Degassers for dissolved gas (CO2 and O2) removal

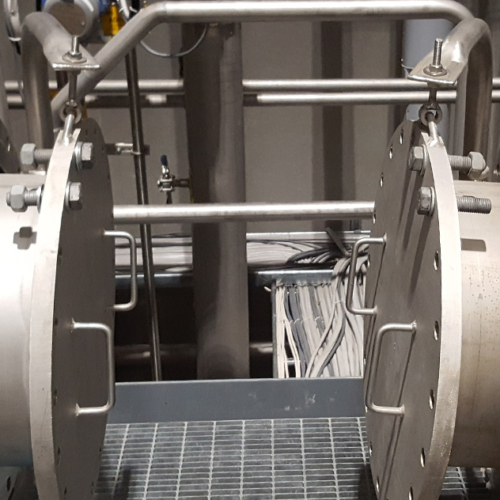

Power stations require a reliable supply of cooling water to run through cooling towers and remove residual waste heat from the plant. Cooling water is generally sourced from large open reservoirs. Prior to entering the cooling system, the raw water requires screening to remove debris, algae and other organic matter.

Hydroflux have a range of medium and high-capacity screening solutions available up to 50,000 m3/hr through a single screen. Hydroflux engineers have supplied screening systems for some of the largest desalination plants in Australia. Our experience makes us the ideal partner for industry when implementing high efficiency, low maintenance screening systems.

Our screening systems can be manufactured in stainless steel for freshwater intakes or duplex and super duplex for seawater applications.

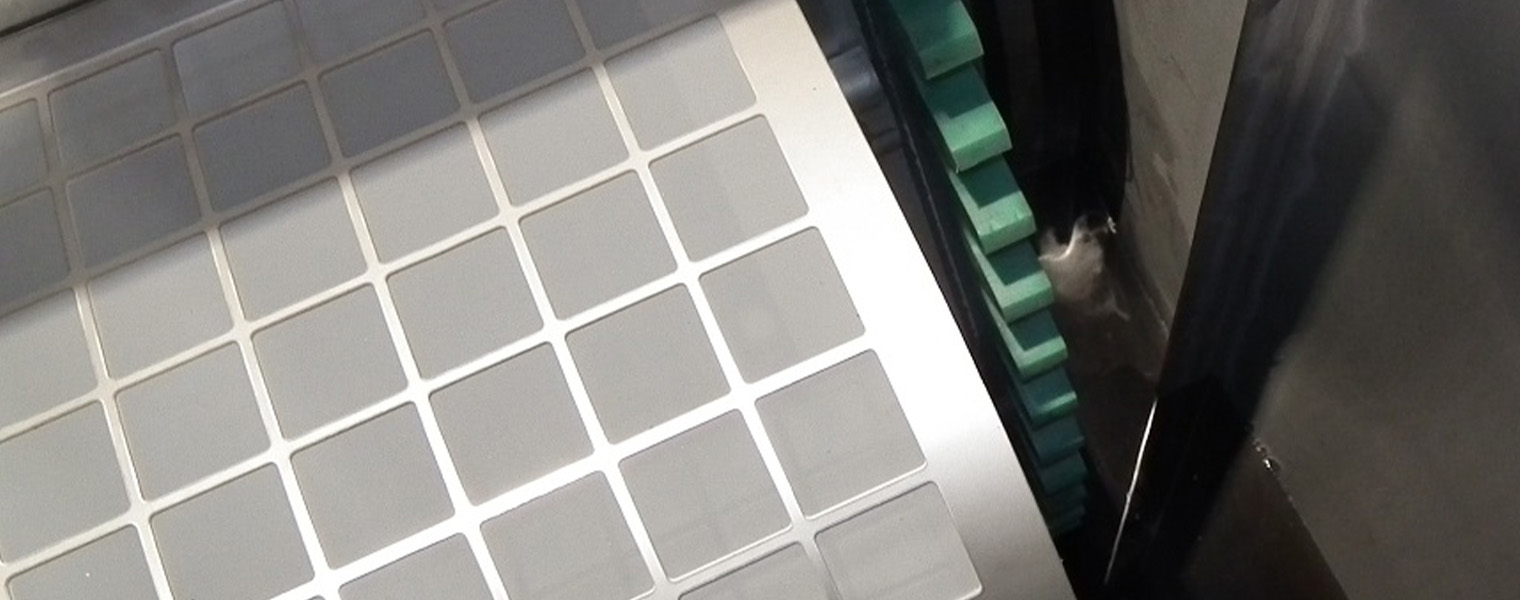

Filtration degree down to 55 µm are possibly within our high capacity Flooscreens.

Hydroflux Solutions

Hydroflux offer a complete range of demineralized water and condensate polishing solutions for power stations including:

- Manual and automatic raked bar screens

- Medium and high-capacity drum screens

- High capacity travelling dual flow basket screens

- Dissolved Air Flotation for algae treatment

Hydroflux employs qualified civil, mechanical, chemical and electrical engineers plus a team of experienced project managers, site supervisors, commissioning engineers and service technicians based in offices in most capital cities providing a local presence throughout the duration of the project.

All projects are conducted under externally approved occupational health and safety, and environmental management systems.

Hydroflux is Australia’s first Water-tech company to achieve Climate Active certifications which means his means you are engaging with a carbon neutral organisation without increasing your carbon footprint and you are supporting positive and verified action on climate change.

Construction of a turnkey wastewater treatment plant at a new food production facility in SA.

Hydroflux can complete all the following works in-house which are typically required to construct a wastewater treatment plant.

- Process design, development of PID’s and HAZOPS reviews

- Establishment of the most suitable wastewater treatment plant layout

- Equipment and component selection

- Civil and building designs including preparation of documentation for council or other regulators

- Electrical design and programming

- Project management and site supervision

- Environmental / Occupational health and safety plans and report

- Quality assurance plans

- Earthworks, civil works, building works, mechanical and electrical installation

- Commissioning, training and documentation as required.

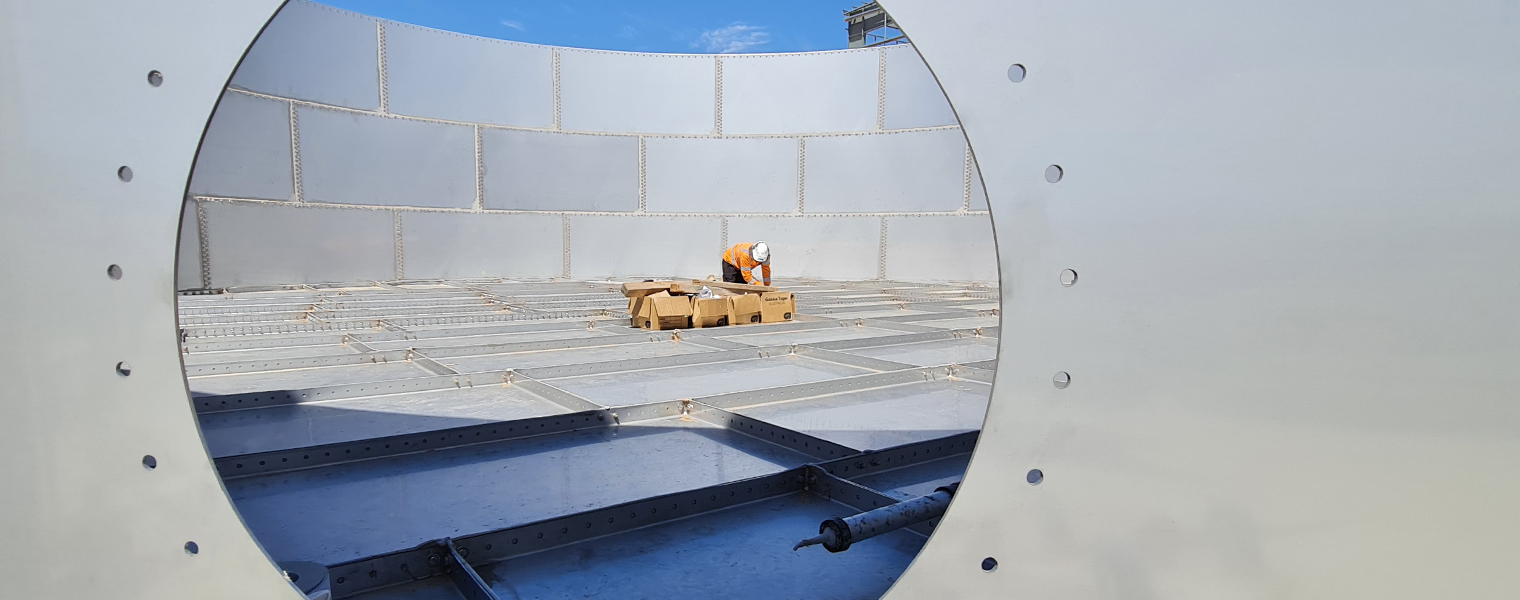

Stainless steel panel tanks are often used for aeration tanks.

The utilities division provides the link to integrating the Hydroflux® businesses by providing a comprehensive support network for customers throughout Australia.

Hydroflux Utilities provides virtually any form of demineralised water management programs including:

Chemical optimisation

Hydroflux has a comprehensive range of coagulants, antiscalants, acids/alkalis, oxidizing/reducing agents and other chemicals suitable for conditioning process water feed prior to and after treatment. We also offer a range of proprietary cleaning and sanitizing agents for membrane plants. Our chemists work hand in hand with the project delivery team to develop the most appropriate chemical program tailored specifically to individual sites needs.

Preventative maintenance and service

Hydroflux process water systems are designed to run autonomously, with the intention to minimise service and maintenance costs across the lifespan of the plant. Our engineers and technicians will discuss service and maintenance programs with you during the design and construction of the treatment plant so that the sites specific maintenance needs are taken into consideration prior to start-up. Hydroflux offer bespoke maintenance agreements, from routine preventative maintenance, periodic service and overhauls, to complete plant operation. Our technicians are available 24/7 to attend to unforeseen breakdowns.

Remote monitoring

Our proprietary HyCONNECT™ remote monitoring system is installed in all our process water plants as standard, enabling instant online technical support and troubleshooting. Specialty solutions are offered for remote locations with reduced cell coverage. No matter where you are, our team of specialists are never more than a phone call away.