How Capturing Biogas Can Reduce Your Greenhouse Emissions from Natural Gas & Coal

March 31, 2021

Could you be reducing carbon emissions from fossil fuels in your business through the production and use of Biogas? Hydroflux can assist you with identifying and implementing changes in your business to achieve your net zero greenhouse gas emissions target.

Global, national, state and industry bodies are emphasising the criticality of reducing greenhouse gas emissions to minimise the impacts of climate change on our global environment, industries, and lifestyle.

In the examples of meat and dairy producers provided below capturing biogas to replace thermal coal or natural gas as a fuel for a boiler could save over 20,000 tonnes of C02 emissions per year. This is the equivalent of taking 9,000 cars off the road or the average greenhouse emissions of 2500 to 3000 Australian homes.

Many industries such as the Meat & Livestock Association of Australia (MLA) and many water utilities have adopted to achieve a carbon neutrality target by 2030 (CN30). All states and territories have adopted a net zero emissions target by 2050 (CN50). This typically involves an interim target for 2030. Others, such as the ACT have gone a step further and are targeting carbon neutrality by 2045 (CN45).

Anaerobic treatment of wastewater is a popular and proven method of wastewater treatment in many industries such as meatworks, rendering facilities, piggeries, poultry, dairy processing, and others.

Biogas is both a significant source of greenhouse gas (GHG) emissions and energy and represents a true win-win if captured and used. Capturing and utilising the gas produced by a digester or covered anaerobic lagoon [CAL] provides unique advantages. The biogas provides an alternative energy source for your plant to reduce the use of fossil fuel.

All fossil fuels add to the carbon emissions ledger as they are removing previously sequestered carbon from its historical underground storage and release carbon into the environment whilst combusted. In addition to that, the mining, drilling and transport of fossil fuels from the source to your door add further to the emissions tally.

In comparison, biogas created by treating your own waste or wastewater is already produced on your premises and can be used to support the energy demands of your business.

Utilising biogas as an alternative energy source for a boiler provides a simple and ready to use alternative fuel to reduce or replace your reliance and use of coal or gas to fire your boiler.

The global warming potential of 1x tonne of methane released to the atmosphere is equivalent to 25 tonnes of CO2 emissions.

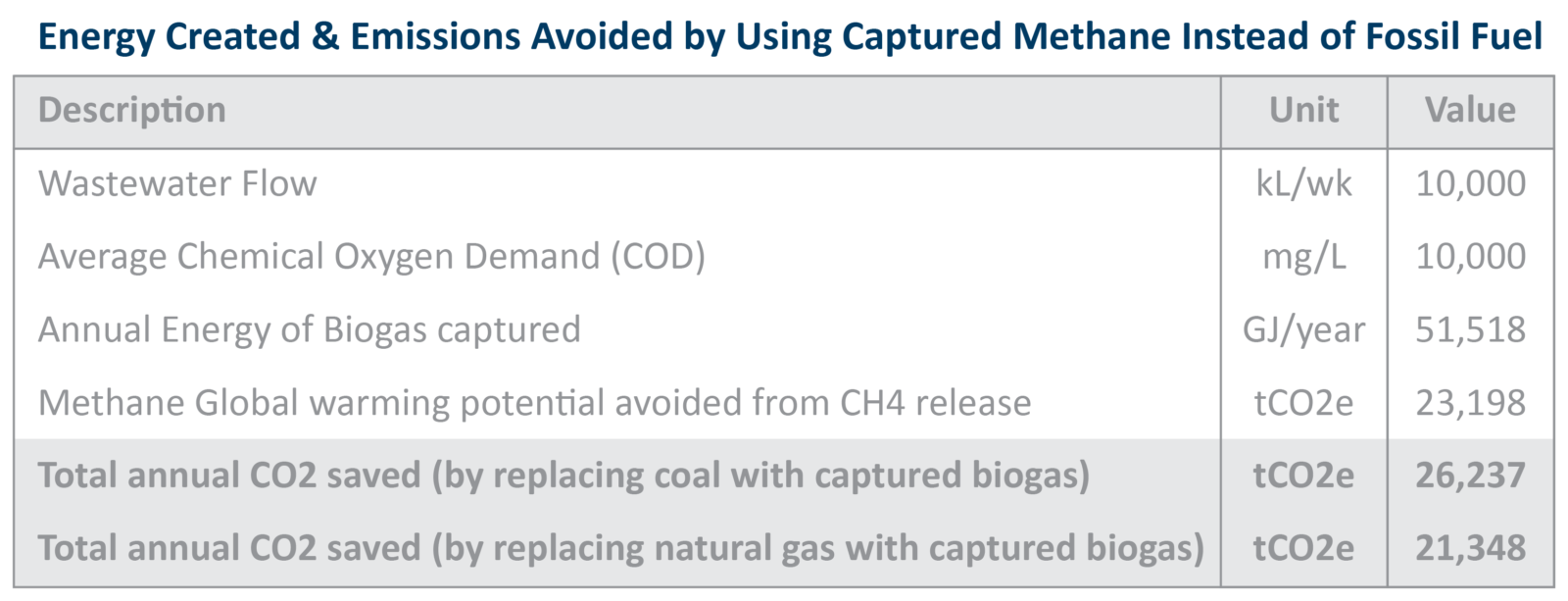

This example shows the possible annual CO2 emissions savings from a plant with a wastewater stream of 10,000m3/week and with an average COD loading of 10,000mg/litre, creating approximately 180,000 m3 of biogas per month. This could typically be achieved with 1x large covered anaerobic lagoon.

In an order to convert the above carbon reduction values to plant sizes, we have created the below reference table. Please Note that wastewater volumes and organic loading rates can be quite different from site to site, depending on the processes and infrastructure used on site. Please refer to your own plant data as a more accurate reference.

Hydroflux can help you to reduce GHG emissions, achieve your targets and improve the sustainability of your business, please give us a call to see how we can best help.

Want to stay up-to-date with what is going on? Click Here to follow our Page for the latest updates.

Up Next

Wells for World Water Day 2021

Categories

- Tradeshows

- Climate

- Community Engagement

- Corporate Announcements

- Group News

- Newsletters

- Product News

- Project Announcement