Product News

Paxton WWTW – Another MBR Pre-screening Installation for Hydroflux

The Paxton Wastewater Treatment Works (WWTW) serves the townships of Paxton, Ellalong and Millfield. The treatment plant process 430kL per...

HUBER Inclined Screw Press – Two Decades of Application Knowledge

It was twenty years ago that the first HUBER Inclined Screw Press made its way into Australia as a part...

Hygienic HyPURE® System for Food and Beverage Production

Hydroflux have completed commissioning of a new 2.4 MLD water treatment plant for an iconic Australian soft drinks manufacturer in...

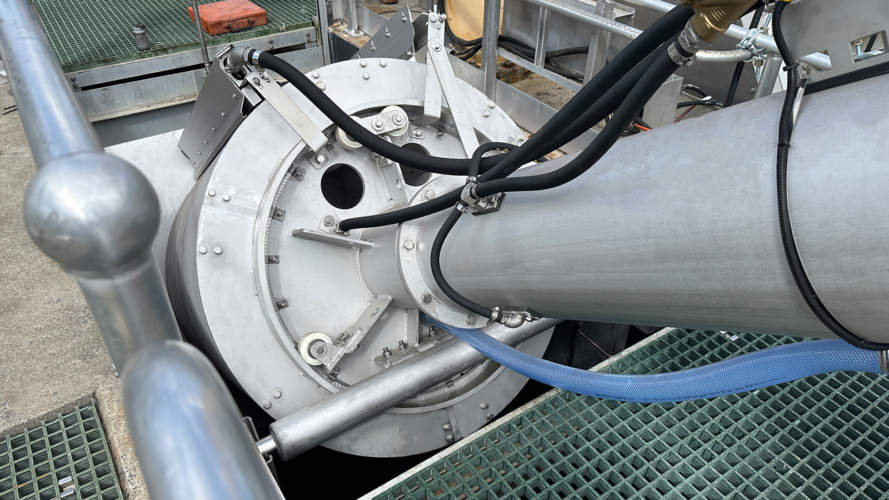

Protecting Advanced Biosolids Treatment Facilities with Strainpress®

As biosolids facilities within a sewage treatment plant reach capacity, several options can be considered when determining ways to increase...

From Greasy to Green: Sustainable Wastewater Solutions with HyDAF-GT

The drive for water security has placed pressure on industrial and commercial businesses that discharge into a sewer network to...

Achieving Tighter Limits for Pond-Based Treatment Systems with HySmart®

Across Australia and New Zealand aerated wastewater ponds are used by industrial manufacturers to provide a level of treatment that...