Prepared Foods

Hydroflux Industrial manufactures high quality wastewater treatment equipment and also design and construct turnkey wastewater treatment systems for all types of Food Processing Plants.

At Hydroflux Industrial, our engineers are fully conversant with the internal production processes of food production and as such, we understand the sources of the wastewater. This enables us to design complete treatment plants that work efficiently, economically and consistently under all conditions.

We have a comprehensive range of primary treatment equipment such as screens and dissolved air flotation system plus advanced biological processes including sequential bioreactors, membrane bioreactors and moving bed bioreactors.

More Information

Milk Processing wastewater

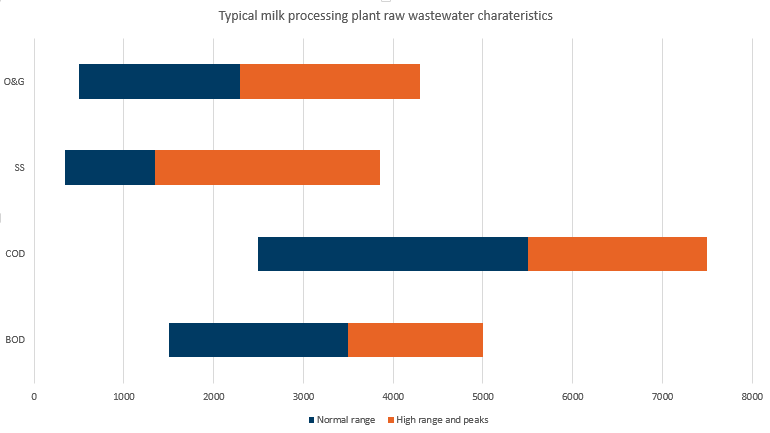

In general, wastewater from milk processing factories contains high concentrations of organic material such as proteins, carbohydrates, and lipids. These substances result in elevated levels of suspended solids, oil and grease, biological oxygen demand (BOD) and chemical oxygen demand (COD).

The actual composition of the wastewater from each facility depends on the actual production methods employed, but from the point of view of a wastewater treatment designer, there are adequate similarities to enable designs to be made, even for Greenfield sites.

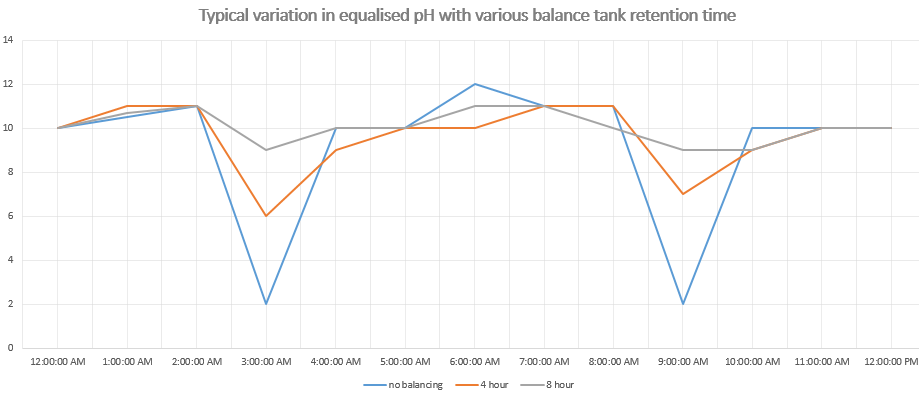

The majority of the wastewater comes from cleaning processes and cleaning of equipment that has been in contact with the milk. Due to a variety of sterilising agents and various acidic and alkaline detergents used in the cleaning process, the pH of the wastewater varies significantly from as low as 2 to 12 and sometimes even higher. Because of this considerable fluctuation in pH, wastewater balancing is essential for all milk processing plants.

As the most commonly used CIP chemicals used are sodium hydroxide, nitric acid, phosphoric acid and sodium hypochlorite, wastewater from milk processing plants will also contain quite high levels of nutrients and sodium which can also require addressing in a wastewater treatment plant.

A further consideration of wastewater treatment designers is the frequency of shock loads experienced at milk processing plants. Although hopefully, not a common occurrence, spills, equipment failure or operational errors do occur resulting in short term very high effluent loads. Considering that the BOD of milk is over 100,000mg/L, the impact of a spill can be quite significant to the operation of the wastewater treatment plant.

At Hydroflux we are familiar and experienced in treating wastewater from dairies and design our treatment plants to perform, and perform consistently under all conditions.

Typical raw wastewater characteristics are shown in the chart below

Call on 1800 801 291 to speak to one of our dairy experts

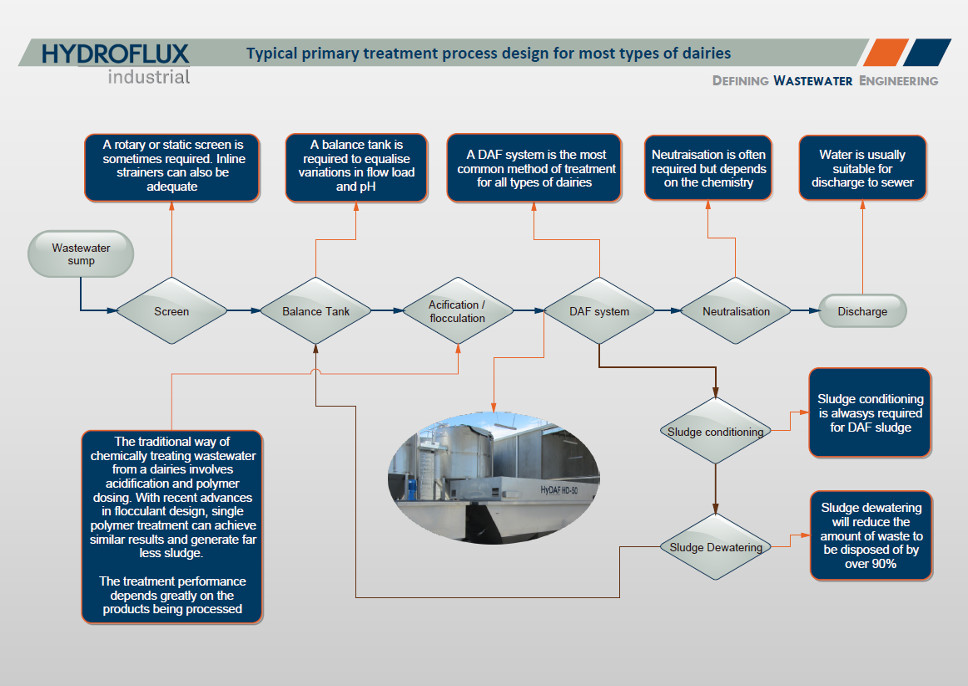

Primary Treatment

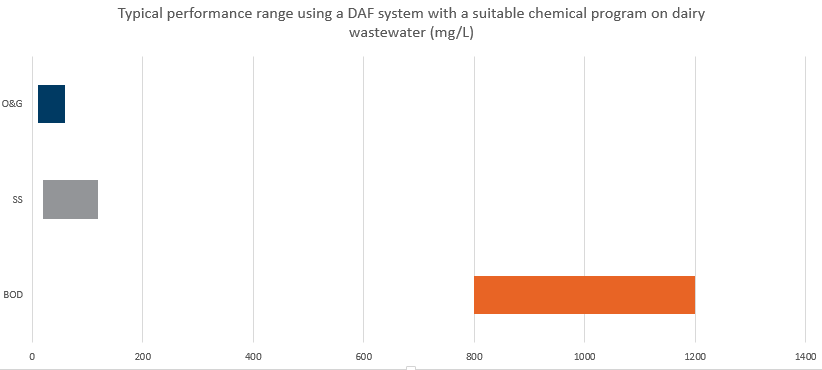

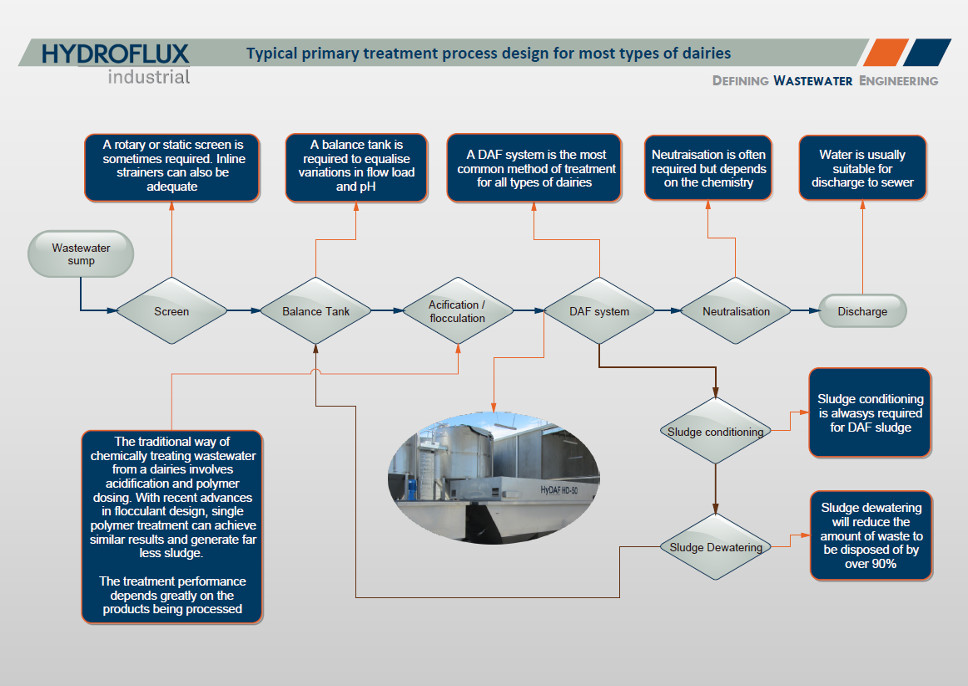

Primary treatment of wastewater from milk processing plants is a generally considered to be good practice as a high percentage of fats and grease, thus BOD / COD, can be quite easily removed which significantly reduces the load on any secondary plant. In many cases where wastewater is being discharged to sewer, primary treatment alone will be the only requirement

Primary treatment process solutions for dairies has not changed in many years and dissolved air flotation is still the system of choice. The effectiveness of a DAF system depends on a number of factors including; pre-screening systems, the chemical program applied and the wastewater balancing facilities.

Wastewater balancing is essential in dairy wastewater treatment plants due to the significant fluctuations in load but more specifically in pH. Inadequate balancing will certainly result in high chemical usage to control the pH but can also result in performance issues. The following chart is an example of the pH fluctuations in dairy wastewater over time.

Screening on dairy wastewater is not always necessary, but if large solids and foreign objects can reach the treatment plant, some form of screen should be considered to protect downstream equipment. In line strainers are quite common if the solids load is low, otherwise rotary screens are ideal (see here for our range of screens).

Chemical treatment of the wastewater prior to the DAF system is essential in dairy applications as the high pH usually encountered results in solubilisation of fats. The most traditional chemical program is to acidify the wastewater and dose polymer to aid in the flotation process. Other options include using a range of coagulants which will reduce acid usage or due to more recent advances in polymer design, a high dose of polymer can be almost as effective, at a considerably lower cost.

Find below a typical primary treatment process diagram.

Call on 1800 801 291 to speak to one of our dairy experts.

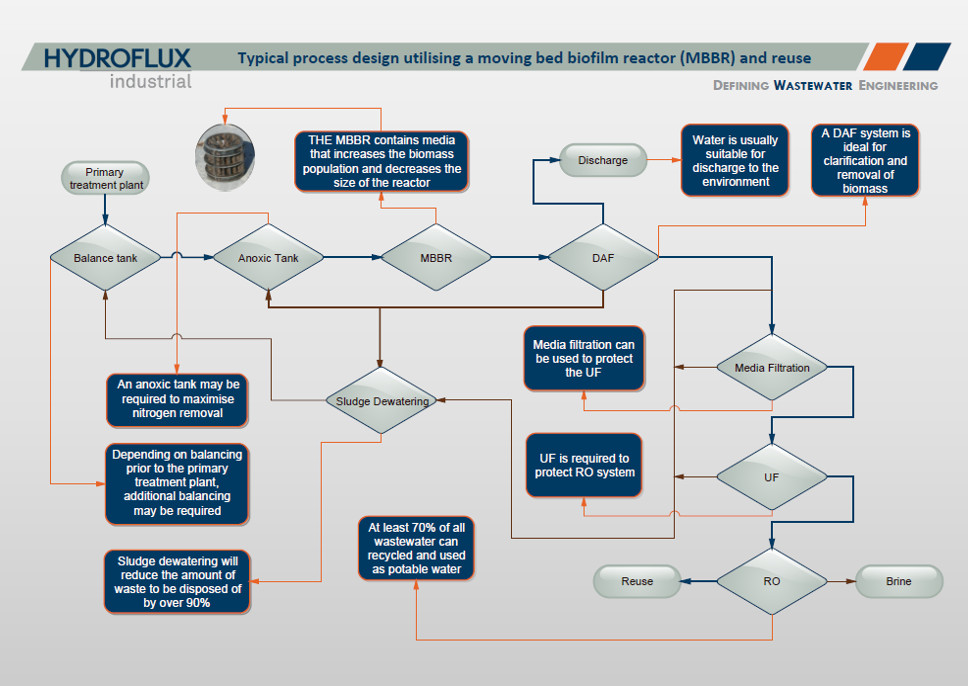

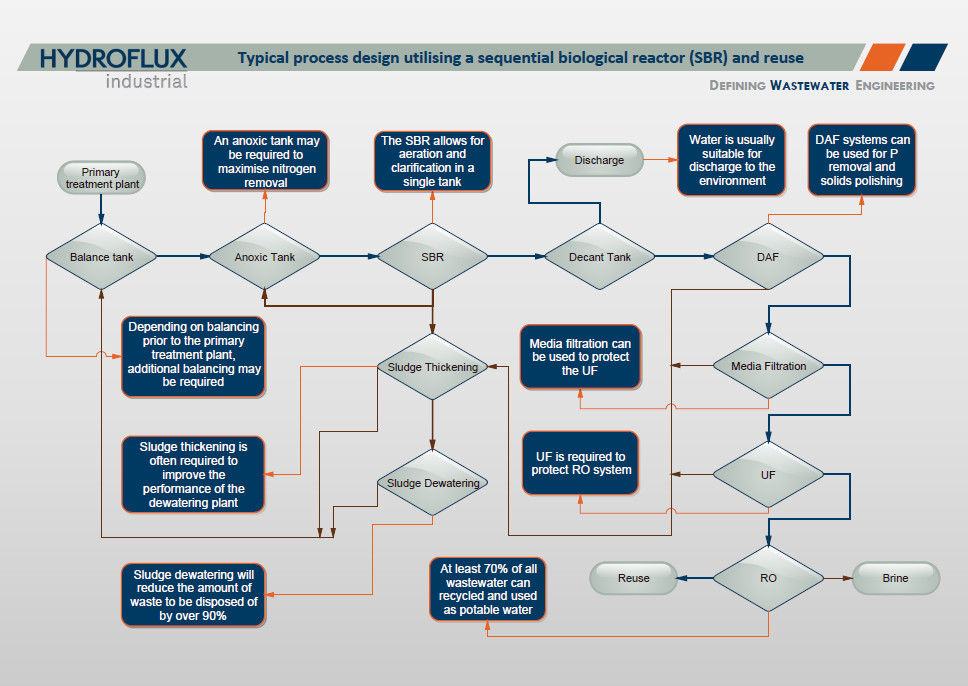

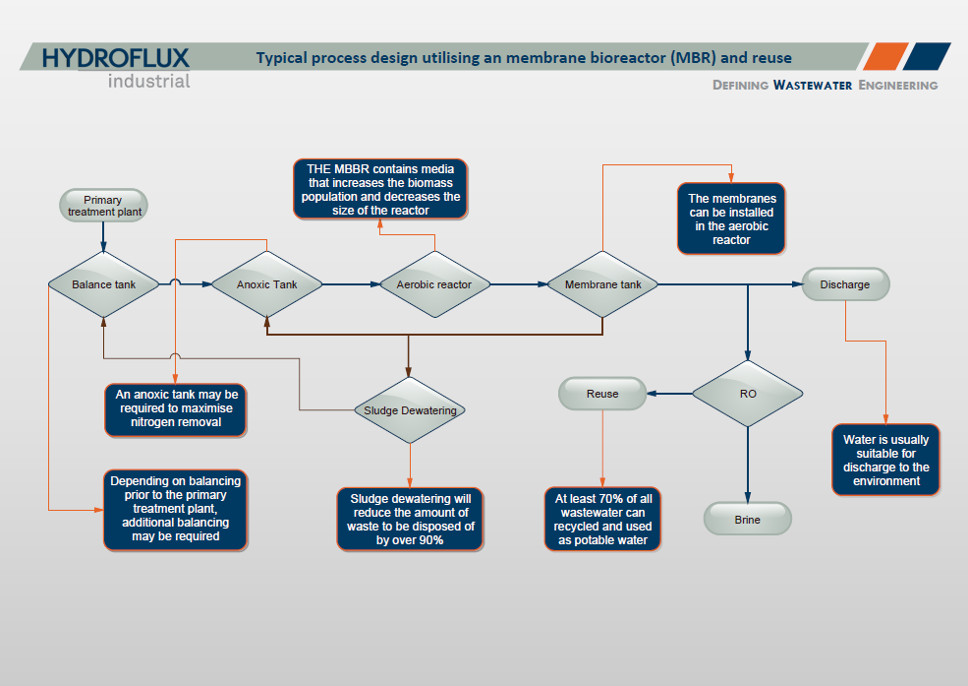

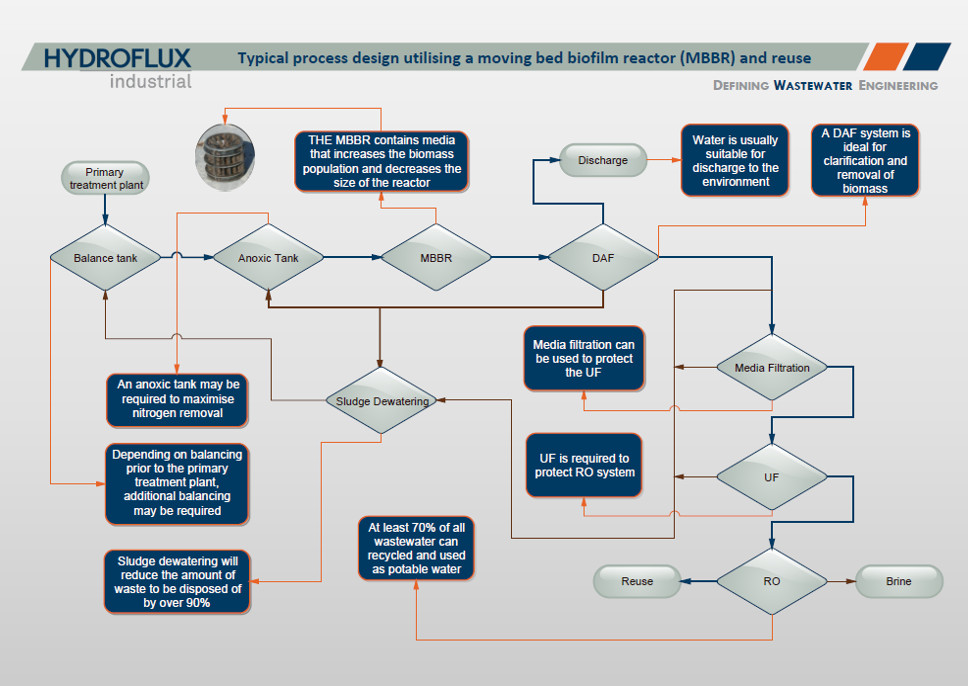

Biological Secondary Treatment

Using biological treatment, can treat wastewater to achieve very low levels of organics and nutrients. Aerobic treatment can allow wastewater to discharged to the environment or with tertiary treatment allow for reuse.

Commonly used systems include lagoons, conventional activated sludge systems with advanced aeration , sequencing batch reactors, moving bed bio reactors and membrane bioreactors.

Aerobic biological treatment for the treatment of biodegradable wastes has been used for many years and can be designed to reduce influent BOD by 95% or more. As wastewater from dairies is highly biodegradable, such systems are ideal and quite common practice.

In determining what the most suitable biological process is, a number of factors need to be taken into account. These include; the performance requirements, the land area available, energy costs and efficiency, and waste biomass production.

Of particular note in terms of performance requirements are the increasingly stringent nutrient limits being imposed in all states and territories of Australia. Removing organic material (or BOD) is relatively simple and energy efficient whereas nitrification and denitrification processes require considerably more power.

The type and size of biological system also depends on the upstream treatment methods. Typically due to the cost of operating a biological plant, upstream treatment should be optimised for maximum economic performance.

As there are so many variations to biological plant deisgn, we invite you to have a look at our web pages on this topic here and contact us if you require any specific information.

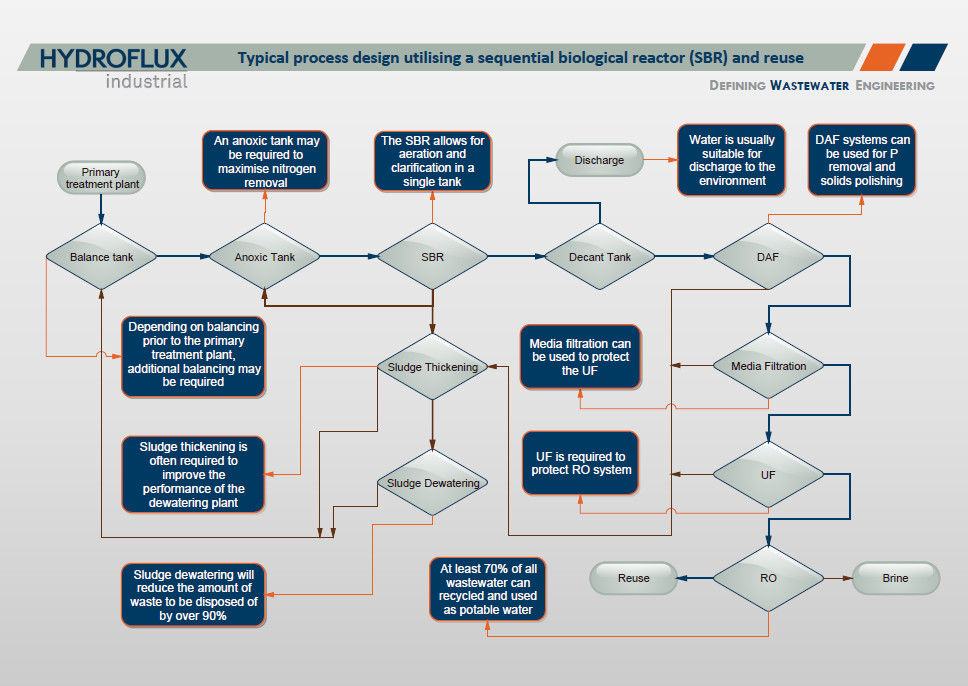

Some typical process diagrams can be found below:

Process diagram utilising MBBR

Process diagram utilising MBR

Call on 1800 801 291 to speak to one of our dairy experts

DAF sludge disposal options are becoming more restrictive, particularly due to the limitation on pig feed and the high costs of liquid waste disposal.

The HUBER screw press by Hydroflux can dewater dairy DAF sludge and achieve over 40% dry solids which equates to a volume reduction in excess of 85%

Please contact us for more information or click here for details on the screw press and trial unit.

Call on 1800 801 291 to speak to one of our dairy experts

Screens

Screens of all varieties including wedge wire or perforated mesh in above ground and in channel designs. (more info)

Dissolved Air Flotation

Performance and quality DAF systems purpose engineered by Hydroflux Industrial. (more info).

Membrane Bio Reactors

Hydroflux Industrial MBR’s are becoming increasingly popular for industrial wastewater treatment due to its small footprint, reliably, decreasing life-cycle costs and the ability for wastewater reuse.(more info).

Moving Bed Biological Reactors

The Hydroflux Industrial Moving Bed Biological Reactor MBBR is a high rate flexible biological process designed specifically for industrial applications.(more info).

Sludge handling systems.

Sludge thickening , dewatering , drying and conveying systems for primary and secondary sludge. (more info)

Complete Systems

Hydroflux Industrial do not only specialise in the design of high quality biological processes but will also design and construct entire turnkey wastewater treatment plants.(more info).

DESIGN CONSTRUCTION OPERATION

Engaging a professional wastewater treatment company to look after the entire wastewater project is a convenient, economical and hassle free option for industry.

Hydroflux Industrial can provide all process design works, manufacture and fabrication, construction and even complete operation of your wastewater treatment plant.

When Hydroflux Industrial provides complete solutions, we can either undertake a contract on a turnkey basis or work together with building services engineers and other construction professionals such as architects, structural engineers and quantity surveyors to ensure that the project is delivered smoothly, without interruption and on time.

BUILD OPERATE TRANSFER (BOT) FINANCING

The Hydroflux Group is able to offer a Build Operate & Transfer (BOT) option for water and wastewater assets in Australia and New Zealand. This innovative partnership arrangement strengthens existing strong bonds between Hydroflux and their customers for the long term.

Hydroflux, represented by a special purpose vehicle dedicated to the project, supplies the design, construction, financing, and operation of the water or wastewater plant. The plant is transferred to the client at the end of the contract, which is generally around 10 years.

Hydroflux also purchase existing water and wastewater plants on a similar basis, which releases cash to our clients for either returning or distributing to investors or for funding other investments in their core business.

The multidisciplinary structure of the Hydroflux group including design, construction, equipment supply and operation makes Hydroflux the ideal BOT water and wastewater partner.

Please contact Hydroflux if would like to explore the option of either acquiring a new water or wastewater facility without capital outlay or would like to free up cash by selling your existing water or wastewater assets.

Process Diagram

Typical primary treatment process for dairies

Process diagram utilising SBR